Boost Your Packaging Process with the 4-Color Flexo Printer Slotter Machine

Enhance your packaging efficiency with Keshenglong & Shinko's 4-Color Flexo Printer Slotter Machine. This advanced solution streamlines your printing and slotting processes, ensuring vibrant colors and precise slots for top-notch results. Embrace innovation and elevate your operational productivity. Optimize your workflow today with our cutting-edge technology. Discover more about how our 4-Color Flexo Printer Slotter Machine can transform your business objectives efficiently.

- What is a 4 colour flexo printer slotter machine?

- Key Benefits of Using a 4-Color Flexo Printer Slotter Machine

- 1. Increased Printing Efficiency

- 2. Superior Print Quality

- 3. Cost-Effective Production

- 4. Versatility in Packaging

- Why Choose a 4-Color Flexo Printer Slotter Machine Over Other Machines?

- Applications of the 4-Color Flexo Printer Slotter Machine

- 1. Packaging Industry

- 2. Custom Box Production

- 3. Non-Packaging Uses

- How to Choose the Right 4-Color Flexo Printer Slotter Machine for Your Business

- 1. Production Volume and Size

- 2. Customization Options

- 3. Maintenance and Durability

- 4. Cost and ROI

- Maximizing Efficiency with Your 4-Color Flexo Printer Slotter Machine

- 1. Regular Maintenance

- 2. Operator Training

- 3. Utilize Automation Features

- Choose the Right Manufacturer for Your 4-Color Flexo Printer Slotter Machine

As the pace of packaging production is rapidly growing, the benefits of achieving high efficiency, quality printing, and flexibility cannot be overestimated. All of you work with flexo printing and are aware that there is always a need to improve efficiency, cut expenses and guarantee that final results are outstanding. This is where the 4-color flexo printer slotter machine comes in. Here in this article we are going to focus on why this machine should be in your production line especially for any business that wants to minimize the time it takes to package their products.

What is a 4 colour flexo printer slotter machine?

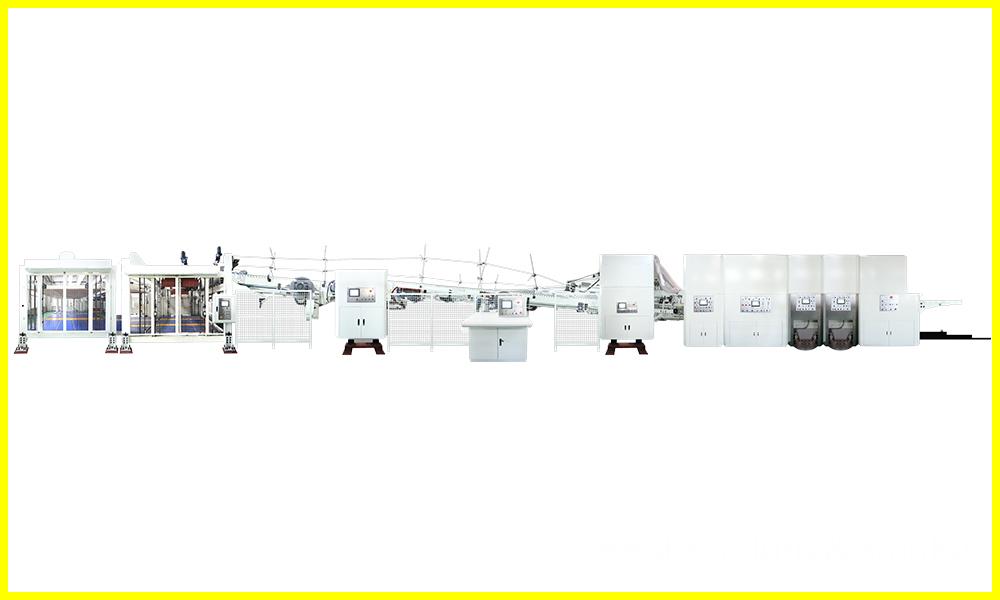

The 4-color flexo printer slotter machine at its fundamental level involves the process of printing four colors on cardboard or corrugated material and at the same time slotting, folding and even die cutting. This particular productive tool involves both the process of printing and slitting hence suitable for packaging industries. This integration of the functions essentially means that the machine saves a lot of time, effort and resources in a bid to produce quality prints.

Since it is capable of making four different colors in one pass, it is a very useful machine for any business that requires quality printed packaging. Other features include servo driven technology and quick change over systems which perfectly fit the 4-color flexo printer slotter machine for high volume productions.

Key Benefits of Using a 4-Color Flexo Printer Slotter Machine

1. Increased Printing Efficiency

The first advantage of a 4-color flexo printer slotter machine is the efficiency that a flexo printer gains through the use of the slotter machine. They pointed out that four-color printing can be done in one pass, which can now be widely recognized by businesses, enabling them to save a lot of time compared with traditional multi-pass methods. As a result of this improved speed, companies in particular can increase productivity, which allows them to publish high quality newspapers within the shortest time possible.

2. Superior Print Quality

The 4-color flexo printer slotter machine is the best slotting machine in terms of the quality of the prints it produces. Flexographic printing employs high quality of ink that results in clear images and bright coloration. These also employ more superior technology that incorporate the correct registration, little if any hue difference, and correct color consistency. When it comes to printing complex graphics, logos, and even basic text, this machine provides the best prints with clear and elegant appearance.

3. Cost-Effective Production

Out of all the industries, it is impressive how the 4-color flexo printer slotter machine can greatly improve costs. Through serial integration, various processes such as printing, slitting, folding and die cutting can be done on a single machine hence no need for many machines. This leads to reduced maintenance expenses and lower number of machines to manage and operate as well as reduced down times. Other aspects in the flexo printer slotter machines include energy saving equipment, which helps to lower the overall costs of running the equipment later on.

4. Versatility in Packaging

One of the interesting features of the 4-color flexo printer slotter machine is its versatility which can meet complicated packaging needs. It can be used in making the corrugated boxes, retail-ready packaging or the most specialized packages. The ability to use different thicknesses of cardboard and materials is a perfect fit for organizations that need both generic and bespoke packaging.

Why Choose a 4-Color Flexo Printer Slotter Machine Over Other Machines?

1. Multi-Color Capability

First of all, the key characteristic of the 4-color flexo printer slotter machine is it can print using four different colors during one run. This is far better than single color flexo printing machines as for every single colour which has to be printed then the machine is able to do it individually. The 4-color flexo printer slotter machine helps save time and effort in the printing of multi-color designs as it is preferred for use by companies designing and manufacturing quality packaging.

2. Better Accuracy and Quality

If one will evaluate the 4 color flexo printer slotter machine with other slotter machines the quality and accuracy are remarkable. Due to servo technology, errors between different prints are little to no-existent and the quality of the prints is high. The results are far better than older flexo machines that either used hand wheel and rod adjustments or lower levels of automation.

3. High-Speed Production

Due to automatication systems and fast setting systems, the 4-color flexo printer slotter machine is designed for a high production rate. Inability to print and slot at the same time, more time is required for the completion of large quantities of prints and additional costs for smaller iteration changeovers decrease the efficiency of this machine.

Applications of the 4-Color Flexo Printer Slotter Machine

1. Packaging Industry

The 4-color flexo printer slotter machines is a very important machinery in the packaging industry especially for those that require flexibility and efficiency in their packaging lines. It is commonly is used for printing and slotting corrugated cardboard, which is the most frequently utilized material for shipping cartons, retail squeezing, and display point-of-purchase. This machine is commonly used in food, beverage, e-commerce industries and many consumer products industries for packaging.

2. Custom Box Production

Custom boxes are an important part of the contemporary packaging that is used in retail shops and stores. The 4-color flexo printer slotter machine is pivotal for companies to print desired graphics and branding on corrugated boxes so as to give new look for products in the market. If it is box for the subscription box, electronics or luxury retail products, this machine provide the freedom to have variety in the look.

3. Non-Packaging Uses

Apart from packaging purpose, the 4-color flexo printer slotter machines is equally effective for creating different types of display and other promotional items. Also, various businesses manage these machines to deliver big-sized printed materials from retail, advertising industries, and occasion arranging, which need to have superior quality multi-colored prints.

How to Choose the Right 4-Color Flexo Printer Slotter Machine for Your Business

When opting for the best 4-color flexo printer slotter machines there are numerous factors that need to be considered. Here are some key considerations:

1. Production Volume and Size

If your business requires lots of copies on daily basis, then you will need a big and fast machine which is able to work on high volumes of prints. On the other hand, if you’re doing only a few hundred or thousand prints, a less cluttered model with fewer options might be just fine. You should therefore consider your production volume or the sizes of your packaging before making further choices.

2. Customization Options

There are many other options available from most manufacturers for the 4-color flexo printer slotter machine that include options for the ink, the slotting of the products or the die cutting that is used. When buying the machine ensure that it meets the requirements of the special type of packaging you will be handling.

3. Maintenance and Durability

In this case, one should search for a known and reputable machine that is easy to maintain, and has the ability of lasting longer. Proper care and maintenance can help you get the most out of your machine and have fewer problems that require repair and eventually cost you money.

4. Cost and ROI

This five figure machine has an excellent return on the investment since it is very efficient and versatile as a 4-color flexo printer slotter machine. Also monitor costs of running the machine, and benefits like low labor and material waste that you’re likely to incur.

Maximizing Efficiency with Your 4-Color Flexo Printer Slotter Machine

To get the most out of your 4-color flexo printer slotter machine, consider the following tips:

1. Regular Maintenance

You need to do all you can to make sure your machine stays in good working condition always and unfortunately the latter is where preventive maintenance comes in. These common procedures can help to increase the longevity of the machine and to reduce downtime constantly.

2. Operator Training

The efficiency of the machine can be increased by competent operators. Hiring an expert to educate your workers on how to use the machine as well as when there are problems that may cause wastage of raw materials should be practiced.

3. Utilize Automation Features

The equipments used in many 4-color flexo printer slotter machines are automatic in nature including features like automatic plate-locking and the quick-change over systems. Ensure you are maximizing these features with regards to minimizing the time taken to set up and gain efficiency.

Choose the Right Manufacturer for Your 4-Color Flexo Printer Slotter Machine

It is therefore important to go for the best 4-color flexo printer slotter machine manufacturer that deals with quality machines accompanied by good support to clients. The machines that we have are some of the best you find in the market; sturdy, reliable, and they give excellent print quality.

The 4-color flexo printer slotter machine is therefore a real game changer for business operating in the packaging production line. By being able to print four colors at one time, cutting down on time taken to print and offering better print quality, this machine is accurate for anyone in the flexo printing business.

If you wish to explore other possibilities of packaging, or consider ordering with us, feel free to contact us at any time, we’ll be glad to provide you with additional information or calculated cost. Here, several options are compared: If you need help with your business, let’s find the best solution together!

For additional information on our 4-color flexo printer slotter machines, or to set up a meeting, call us today. We want your business to be able to run smoother, cheaper, and have higher quality prints with the newest flexo printing equipment!

Recommended for you

How doe's automatic flexo printer slotter carton machine work?

Optimize Your Packaging Production with Jumbo Flexo Folder Gluers from Leading Manufacturers Keshenglong

How to Choose Right gluing corrugated box printing machine manufacturers manufacturer and supplier ?

How to Choose Right corrugated carton flexo printing slotting machine manufacturer and supplier ?

What is Flexographic Printing?

Industry Solutions

What is the lifespan of your folding carton machines?

With proper maintenance, our machines are built to last for many years, providing long-term value for your investment.

How can your folding carton machines benefit my packaging business?

Our machines increase production efficiency, reduce labor costs, and ensure high-quality, consistent carton production.

What industries typically use your folding carton machines?

Our machines are used in various industries including food and beverage, pharmaceuticals, cosmetics, and electronics.

Shipping

What is the estimated delivery time for your machines?

Delivery times vary based on location and order size, but we typically estimate 4-6 weeks for delivery.

Can I track my shipment once it has been dispatched?

Yes, we provide tracking information for all shipments so you can monitor the delivery status.

Leave a message

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2024 Keshenglong&Shinko All Rights Reserved. Designed by gooeyun

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine