How doe's automatic flexo printer slotter carton machine work?

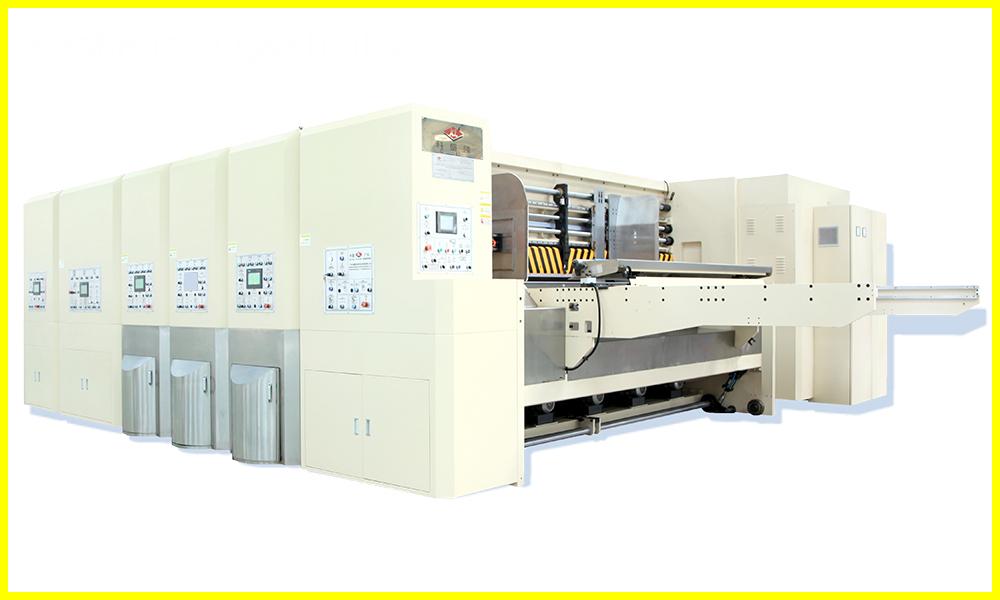

"Discover the efficiency of Keshenglong & Shinko's automatic flexo printer slotter cartridge machine. This state-of-the-art equipment streamlines the printing and slotting process by combining precision flexographic printing with accurate die-cutting and slotting. Optimize your packaging production with a machine designed for high-speed performance, ensuring quality and reliability every time. Learn more about this innovative solution today."

- 1. Flexo Printing (Printing Process)

- 2. Slotting (Cutting Process)

- 3. Die Cutting (Shaping Process)

- 4. Folding (Folding Process)

- 5. Gluing (Gluing Process)

- 6. Ejecting (Final Process)

- 7. Automated and Control Systems

- Summary of Key Processes

- Advantages of Automatic Flexo Printer Slotter Cartons Machines

They are mainly used for carton making, especially the corrugated cartons, and are called automatic flexo printer slotter carton machines. This machine also performs multiple tasks simultaneously, which include the flexographic printing, the slotting, the die cutting, the folding and the gluing. Intended to deliver quality printed, pre-cut, fold and glued cartons within the shortest possible time.

Here's how it works:

1. Flexo Printing (Printing Process)

Text, graphics, or any logos that a manufacturer desires to be placed on the specific corrugated cardboard are printed using the flexographic printing method. The printing technique employs flexo plates, which resemble rubber or photopolymer plates and are most often mounted on a printing cylinder.

Ink application: In the flexo printer, anilox rollers are used, through which the ink is rolled on to the flexo plates. These rollers also help to control the amount of ink the printing surface will receive to a certain thickness.

Printing: Flexo printing: as the corrugated board moves through the printing unit, the inked flexo plates then transfer the printed image to the surface. Flexo printing is also suitable when printing on corrugated materials because the process supports a diverse list of substrates and generates colourful, high-definition images at high printing speed.

2. Slotting (Cutting Process)

Following compilation, the corrugated board must be slotted in order to'set ’ the fold line— the position where the carton would be created by folding. The slotting section cuts the cardboard into the required pattern, which can include:

Slot cuts: To make a little fold for the flaps of the carton to be placed on.

Perforations: However, for easier folding or to make certain designs, the layers have the capability of being manipulated.

The slotter also employs rotary knives to make the cut through the board following a continuous smooth motion. The slotter makes sure that they are cutting well in order for them to fold perfectly and leave little wastage behind.

3. Die Cutting (Shaping Process)

The die-cutting unit shapes the cartons to the required shape of the corrugated board. This process includes using a rotary die or flatbed die cutter in which a series of holes, notches or more elaborate shapes is cut right on the edges of the board. This can include:

Window cuts: To form CCBS regions by extending the board and making recessed or cut-out shapes in the board.

Special shapes: For example, custom-made designs on packaging.

This part of the machine employs dies— these are metal or rubber molds already designed to correspond to the shape of the desired carton or box. Otherwise, the die cuts are accurate to the point that the carton will be easily foldable and indeed erectable.

4. Folding (Folding Process)

After printing, slotting and die cutting processes are done, the corrugated board is transferred to the folding section. The final part of the manufacture is where the sections that have been pre-cut and pre-slit are folded by the machine into the shape of the final carton. It also aligns the folds to sharper creases and makes the assembly of the box possible with minimal effort.

The folding rollers help control the flow of material for better and correct folds.

There is a feature of automatic control between the folding section to ensure that it deals with different sizes and cartons.

5. Gluing (Gluing Process)

The gluing unit, after the folding process, adds the glue in the places where cartons will be bonded together. This is an important step that helps guarantee the form of the carton on the products and, by extension, its sturdiness for the purposes of transportation or stocking.

The structure employs an automatic gluing system that dispenses the rightly proportional glue on the fold or seam of the box.

The glue can also be applied via roller glue systems or nozzle gluing systems in order to achieve an even coating of glue.

The gluing system that is used acts as a means of making sure that after the folded carton has been assembled, it does not easily come apart.

6. Ejecting (Final Process)

After the carton is printed, slotted, die-cut, folded and glued, it is then ready to be produced and ejected out of the machine.

The final transport cartons are ejected mechanically through an ejecting system, which most commonly disposes of them on a conveying system for further processing, packaging or storage.

The ejecting unit makes the packaged bottles easier to arrange, especially for packing, sorting or quality control.

7. Automated and Control Systems

Modern automatic flexo printer slotter carton machines come with advanced control systems that provide the following benefits:

Precision: The products are to be printed and cut into the desired shapes through automated controls at set angles and creases.

Speed: This is because the capacity of the machine is such that it can process large volumes of corrugated board, thus the effectiveness.

Customization: It is quite possible to adapt to new cart sizes or designs; for example, in case the carton needs to be modified, it will not take long to redesign.

Monitoring: Most systems contain digital interface solutions that assist operators in the envisaging of the performance of the pertinent equipment and in diagnosing and altering the functioning as necessary at the same time.

Summary of Key Processes

1. Flexography: Prints a logo or design onto the corrugated board, usually with ink.

2. Slotting: They fold the board after cutting it in order to fit it in his eyes.

3. Die cutting: cutting out of shape or designs on the cartons.

4. Folding: It is used to fold the board into what resembles a carton.

5. Gluing: Covers the surface of the carton with adhesive.

6. Ejecting: The movement of expelling the finished carton for further processing.

Advantages of Automatic Flexo Printer Slotter Cartons Machines

Efficiency: It is a process that integrates several operations within one apparatus, thereby eliminating the use of individual apparatus and efforts.

Quality: Offers effective and efficient printing, cutting and folding—the quality needed for good-looking cartons.

Automation: Automatic systems reduce the roles of human beings as much as possible, increase efficiency and accuracy, and reduce time.

Customization: The flexibility of manufacturing cartons of different sizes and forms in order to fit different packaging solutions.

Basically, an automatic flexo printer slotter carton machine enhances the production of corrugated cartons by increasing efficiency and reducing costs but not quality. Consumers tend to find it even more useful for use in industries that use a lot of packaging, such as the retail, e-commerce and shipping industries.

Recommended for you

Choosing the Right Folder Gluer: Glue Stability and Speed

Smart Folder Gluer Solutions for E-Commerce Packaging

5 Most Popular Types of Corrugated Converting Machines

6+1 Flexo Slotter Solution: Keshenglong’s Answer to High-Precision Corrugated Printing

Green Packaging Solutions: How Keshenglong Promotes Sustainable Production

Shipping

Do you offer international shipping for your machines?

Yes, we offer international shipping and can handle all necessary customs documentation.

What are the shipping costs for your folding carton machines?

Shipping costs depend on the destination, machine size, and shipping method. Contact us for a detailed quote.

Industry Solutions

What kind of technical support do you offer for industry applications?

We provide comprehensive technical support, including installation, maintenance, and troubleshooting services.

Do you offer customized solutions for unique production needs?

Yes, we work closely with clients to develop customized solutions that meet their specific production requirements.

Product

How do I troubleshoot common issues with the folding mechanism?

Common issues can often be resolved by checking the alignment of the folding plates and ensuring there is no debris obstructing the mechanism.

Leave a message

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2025 Keshenglong & SHINKO All Rights Reserved. Designed by gooeyun

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine